Key points

This white paper reports on the investigation and resolution of challenges that come from using electronic flow meters in high-speed batching processes.

High-speed batch dosing is used primarily within the food, beverage and pharmaceutical industries. It increases production throughput and efficiency, as well as saving on cleaning costs associated with more traditional batching processes.

Operating a reliable batch filling process is contingent upon all process conditions being constant – pressure, temperature, viscosity – to ensure repeatability. For high-speed batching systems, additional considerations must be taken into account: choice of equipment, type of flow meter used, piping and overall process design.

Electronic flow meters, such as ultrasonic, Coriolis and electromagnetic devices have no moving parts in contact with the liquid being measured, making them easier to clean for hygienic processes.

The functionality of electronic flow meters also makes them a desirable replacement for the traditional mechanical flow measurement units as they allow for a wider variety of liquids to be used within batching systems.

Though electronic meters can be very accurate, they all have a discrete internal cycle time for processing the flow information, which can affect the repeatability within applications such as high-speed batching processes.

Aim of the Investigation

The aim of the investigative trials is to determine the optimum results for high-speed (at sub three second) batching using an Atrato® ultrasonic flowmeter that can be achieved with an accuracy higher than ±0.5%.

Summary of Conclusions

Significant increases in high-speed batching performance were shown using the Atrato® ultrasonic flowmeter, bespoke AI learning software, and an appropriate system set-up in laboratory conditions. Sub three second accuracies higher than ±0.05% were achieved during the investigation.

Extrapolating from the results, accuracies of ±0.25% should be readily achievable in factory applications using Titan’s ultrasonic meters and augmented software. Additionally, batching periods of less than one second were deemed to be perfectly feasible in the ‘real world’ with some additional adjustments.

High-Speed Batching Problem

Flowmeter resolution or granularity has always been a potential issue with batching processes. Electronic flow meters, such as ultrasonic, Coriolis and electromagnetic, usually have fixed measuring periods, presenting a trade-off between response time and affordability.

This inflexible timing window does not pose a significant issue when dispensing more traditional large batches. However, with lower volume and high-speed delivery periods the problems encountered with flow control can be substantial.

An electronic flow meter, such as Titan Enterprises’ Atrato® ultrasonic flowmeter, measures the flow every 3ms but calculates and returns the result at a cycle time of approximately 50ms. This is perfectly acceptable for most applications but if a high-speed dispense is required with excellent accuracy and repeatability, this 20Hz update rate can present a problem. Results can show a potential 4% spread within the batch, before taking into account the installed system accuracy and repeatability.

This paper reports on trials undertaken to improve this higher speed dispense repeatability to optimum levels.

Mechanical meters are widely used in normal batch filling processes but do have their limitations. Small turbine flow meters are highly effective for low viscosity dosing systems, giving a relatively large number of pulses for a given volume of liquid.

However, the moving parts within the flow line make them less suitable for viscous liquids. Positive displacement flow meters (such as oval gear flowmeters) perform particularly well with more viscous liquids but often have a very low frequency output resulting in poor granularity.

Mechanical flow devices can be problematic for any hygienic requirements, so electronic flow meters with no moving parts are desirable for high-speed batching, as they cope with a wide variety of liquids and can be easily cleaned. However, all electronic flowmeters bring this low granularity to the fore.

Even though the basic electronic meter resolution can be set to a very high number, such as 100,000 pulses per litre, the flow meter’s processing cycle time may override this resolution if the batch time is too short.

System Set-Up

The initial flow rig set-up is shown in Diagram 1. The flow meter selected for this trial is Titan Enterprises’ Atrato® flowmeter, an ultrasonic measuring device.

The set-up comprised a very simple header tank feeding the flow meter/valve assembly. Batch samples from the meter/solenoid were weighed on a precision calibrated laboratory balance.

The dispense valve chosen for the test was a concentric direct current solenoid with highly repeatable characteristics. Measured water samples were returned to a storage sump containing a standard pump which pumped the water back up to the constant head storage tanks.

Reference Tests Using a Standard Ultrasonic Flow Meter

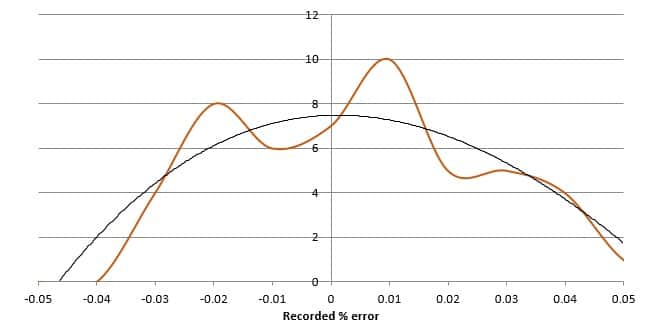

An Atrato® flowmeter with a 42ms sample time was used for these reference tests to judge the magnitude of the problem. Different batch sizes were recorded and the errors plotted in Graph 1. These results show the potential repeatability issues with smaller batch sizes and reduced cycle times. The longest period equates to a 300ml batch, whilst the shortest is just over 15ml. The calibrated laboratory balance had a resolution of 0.001g and a maximum weight of 450g.

Graph 1 illustrates the theoretical error from just the Atrato® meter’s internal cycle time; other system variables will only increase this uncertainty.

Graph 2 clearly demonstrates that the longer the batching time, the better the accuracy with 40 second runs achieving an overall repeatability of ±0.1% over the set. The three second batch time shows ±1.3% and the 20 second batch time recording ±0.3%, (with the exception of the first run which we determined to be an erroneous reading). This is largely in line with the potential repeatability errors from the system cycle time shown in Graph 1.

A standard dc solenoid was used for this initial series. It has discrete repeatability characteristics and this, coupled with a mechanical relay and the meter cycle time, give the scatter seen in Graph 2. One should note the cycle time would statistically place the errors as over dispense because the stop total would not be given until the end of the current measurement period, but the results shown are the scatter around the average volume dispensed.

Tests Using a New AI Software in the Atrato® Flow Meter.

The parameters for this test were 150ml volume dispensed and a batch period of approx. 2.8 seconds.

The flowmeter was reprogrammed with new software designed to overcome the limitations of the standard meter’s cycle time and compensate for the solenoid valve’s response time. From Graph 1, the expected accuracy would be around 1.5% in the standard Atrato® flowmeter software. The results recorded demonstrate a significant improvement in system accuracy.

Graph 3 shows the initial results prior to stabilising the temperature and pressure on the flow rig. The repeatability is still excellent and an order better than could be expected with the standard Atrato® software. The right hand (red) scale is the error from average and the left hand (blue) scale the actual volume dispensed.

To ensure repeatable results, the test set-up had to be as stable as possible to remove extra external variations in the system. The rig was reconstructed to be a temperature stable constant water head arrangement to meet this requirement.

A continually recirculated system was designed, consisting of a series of storage tanks with a high surface area for temperature stability and a pump sump. The storage tanks were positioned high above the batch test system therefore maintaining a constant pressure from the discharge piping to the flowmeter.

The flowmeter was attached to the inlet of the solenoid valve, which was fitted with a non-drip nozzle. All measured water samples were returned to the storage sump containing a very low power pump which pumped the water back up to the farthest storage tank from the discharge port.

The rig design (as pictured in Diagram 2) was refined to increase water volume, thermal mass and radiating surfaces. This enabled a thermal equilibrium just 1.5 degrees above the ambient without the necessity of a cooling circuit.

Graphs 4 and 5 show the test results using this adapted rig design. Maintaining constant pressure and temperature to eliminate these variations in the system, 50 sample tests were recorded.

Graph 5 indicates a Median of 0.0049% and Standard Deviation of 0.022%.

As a matter of interest, a series of single drips were also measured. They weighed between 0.035 to 0.045 grams. This was equivalent to approx. 0.025% of the dispensed 150-gram volume.

Conclusion

Titan Enterprises’ Research and Development is driven by real problems experienced in industry. A bottling process plant in Europe identified the challenges they were experiencing by shifting to a high-speed batch process using electronic flowmeters and asked Titan to explore alternatives to standard flow measurement devices.

Using constant process flow conditions and bespoke specialised interactive and predictive batch software, Titan Enterprises demonstrated high repeatability with short dispense periods utilising the Atrato® ultrasonic flowmeter. Sub three second batching accuracies better than ±0.05% were achieved during the investigation

From the results recorded with the bespoke AI software, batching periods as low as one second are predicted as achievable with the Atrato® range of ultrasonic flowmeters along with careful system design.