Measure small tanks, silos, pipes

Jeff was looking for an alternative to the proximity sensors he was using in seed storage bins. It needed to work reliably with seasonal temperature changes, use the existing fittings, and not break his budget. The MCP-200 mini-capacitance probe may be just what Jeff is looking for.

This compact sensor for light solids and powders detects when there is a change in capacitance caused by the presence or absence of material using the difference or variation between the capacitance of the sensor and the material being detected. Capacitive technology is well-suited for industrial environments where the temperature fluctuates and remains stable despite temperature changes.

This new BinMaster level sensor features an IO-Link connection and wireless Bluetooth setup which makes it easy to set up and integrate into PLCs or existing control systems. It is easily programmed from a phone, tablet, or PC using Bluetooth. It is extremely versatile offering optional explosion-proof and FDA approvals and an assortment of small fittings and hygienic connectors. The MCP-200 is offered in custom configurations and is available with short lead times.

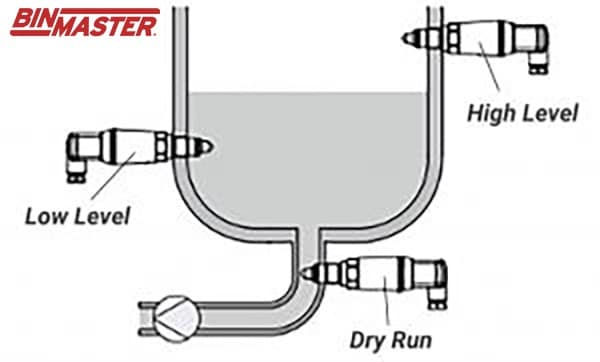

Use the MCP-200 point level detector for monitoring and process control in tanks, vessels, hoppers, or feeders or to monitor pipelines. It is useful in industries like food processing, pharmaceutical manufacturing, seed companies and agriculture or aquaculture use. It can also be used for level detection of plastics and resins, wooden materials and paper, or glass. In process control, the MCP-200 can detect when a hopper is empty to avoid outages that could lead to improper batching or undue wear on equipment.

With protection ratings of IP66/IP67 and IP69, a process temperature range of -40° to 239°F, and process pressure range of -1 to 25, it is versatile enough to install in many industrial environments. Long service life is assured with wetted part construction of stainless steel and PEEK plastic and a durable, chemical and weather-resistant FKM seal material.

Visual alerts via a colorful LED status display make it great (and exciting) for monitoring levels in bins or hoppers Adjustable coloration gives plants the ability to customize alerts to any color on the spectrum they prefer.

This capacitive sensor is ideal for small tanks and hoppers. The visual LED status makes it easy to monitor the status from the plant floor

Food Plant Shift Supervisor

Be like Jeff. Get the BinMaster MCP-200 is for low-cost point level detection in light bulk solids in ordinary, sanitary, and hazardous locations. Have liquids, too? The company also offers the MCP-100 for use in tanks containing liquids.

Contact BinMaster’s sales team to take your inventory system to the

next level with CNCR sensors and IoT solutions for your plant!

BinMaster

- +1.402.434.9102

- info@binmaster.com

- https://www.binmaster.com

- 7201 N 98th St Lincoln NE 68507 US

About us

Operations that struggle with the challenges of inventory management and timely replenishment of all types of powders, bulk solids, or liquids can monitor silo levels on their smartphone, tablet, or desktop with complete solutions from BinMaster. A complete suite of continuous level sensors, point level indicators, material management, and inventory monitoring devices and software simplifies material management while keeping people safe from the risks of climbing silos.

The Lincoln Nebraska, USA company manufactures sensors and software used for monitoring levels in bins, tanks, silos, chutes, and hoppers. Continuous level measurement options include SmartBob cable-based, guided wave radar, laser and 80 GHz non-contact radar, which are all compatible with Binventory™ software. Battery-powered, wireless laser level sensors are compatible with BinView® or FeedView® web apps for remote monitoring.

The unique 3DLevelScanner measures and maps material for volume accuracy and is the only sensor to generate a 3D image of silo contents. BinMaster is the exclusive worldwide supplier of this unique technology and has commissioned these sensors in bins containing powders and solids for over a decade.

Point level indicators provide automated level alerts using rotaries, diaphragm switches, capacitance probes, tilt switches, and vibrating rod level sensors. Dust detection devices alert to baghouse leaks and unsafe particulate levels. Flow detection sensors prevent cross contamination and assist with FSMA compliance for human and animal feeds. Aeration devices keep powders and solids flowing so they don’t pack in hoppers, along bin walls, or in the cone of the vessel

Robust, custom systems can be developed for a single site or networked for every bin, tank, and silo across a multi‐national operation. Add Stockpile Reports for pile inventory using images from an iPhone or drone to a SaaS dashboard. Monitor livestock feed inventory from a phone, tablet, or PC with the FeedView® web application.

BinMaster is US manufacturer certified to ISO 9001 quality management systems – requirements. For more information about BinMaster, visit www.binmaster.com.

What we do in a nutshell

BinMaster provides accurate inventory management for processing industries that store materials in bins, tanks, and silos.

Where we supply to

UK Ireland, Africa, Asia, Australia, South America, North America

Industries we supply to

Chemicals, Energy and Power, Food and Beverage, Glass Ceramics Cement, Metals and Minerals, OEM, Paper and Pulp, Pharmaceutical Cosmetics Toiletries, Plastics and Rubber, Recycling, Tobacco, Water and Wastewater

Something interesting you may not know about us:

BinMaster is a subsidiary of Garner Industries and has fully integrated CNC machining capabilities.

-

IoT Network Devices for Level Sensors and Monitoring Silo Inventory — BinMaster

-

Bin Level & Bearings — What Grain Operations Need to Know