Advancements in overall efficiency and the ability to handle a wide array of unique chemicals combine to make the air-operated double-diaphragm pump a first choice for chemical processors

In the 60 years since Jim Wilden developed the air-operated double diaphragm pump (AODD) principle; these pumps have in many ways become a victim of their own success.

This is due to their design characteristics that allow them to self-prime, run dry, maintain suction lift up to 30 feet (9 meters or 14.7 psia), withstand deadhead pumping conditions, operate while completely submerged and pass solids up to 3 inches (76 mm) in diameter.

In reality, though, these characteristics have also allowed AODD pumps to be extremely effective in more delicate liquid-handling applications, including those that are prevalent in the pharmaceutical and food-and beverage industries.

The benefits of Air-operated Double Diaphragm Pumps

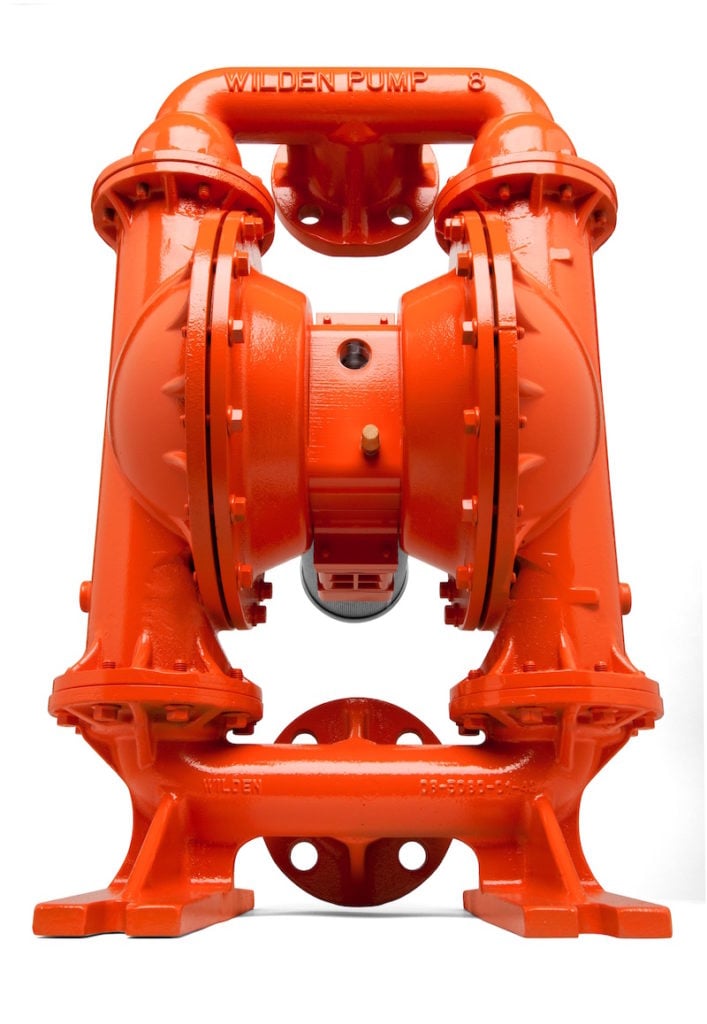

Among the benefits that a Wilden® air-operated double-diaphragm (AODD) pump outfitted with the Pro-Flo® SHIFT ADS can offer chemical processors are significant savings in air consumption, more yield per standard cubic feet per minute (scfm), easy maintenance and the ability to handle a wide range of corrosive or hazardous liquids.

Thanks to a series of technological advancements from Wilden® the AODD can now be considered a true “process” pump, having gained acceptance as such in diverse industries like paint and coatings, ceramics, adhesives and sealants, oil and gas, food and beverage, pharmaceutical and cosmetics.

When one of the largest independent chemical distributors in the United States relocated to a new, larger facility with expanded warehousing, blending, packaging, clean room and warm room areas it needed a pump technology that could perform well in a number of unique operating environments.

The solution was to equip the facility with bolted AODD pumps, which possess the capability to handle a plethora of different chemicals that would need to pass safely through the facility.

Then there was the case of the leader in solvent production for use in the Indonesian paint-and-coatings market which needed to improve the operational efficiencies at its production plants, where the time needed to load and unload holding tanks was becoming prohibitive.

After performing onsite tests, the plant’s operators learned that advanced AODD pump air motor technology could not only reduce the transfer times through higher flow rates, but could do so with decreased compressed air consumption compared to competitive products, thus reducing the operating costs of the fluid transfer.

While these examples may show that AODD pumps can be considered process pumps in critical applications across a wide variety of industries, this has only become possible once some noteworthy refinements in their operation were made.

The Air in There

Despite the fact that AODD pumps have proven their effectiveness in utilitarian liquid-transfer applications, there has always been one annoying glitch in their operation: at the end of every pump stroke, a small, but still significant, amount of air was wasted. This kept the pump from operating at its most efficient and added to its bottom line cost of operation.

Because of that, AODD pump manufacturers – led by Wilden – were always searching for ways to eliminate this problem. This has led to a series of advancements in Air Distribution System (ADS) technology that have enabled the AODD pump to optimise air usage (and cost) while still maintaining its standard-setting operational characteristics.

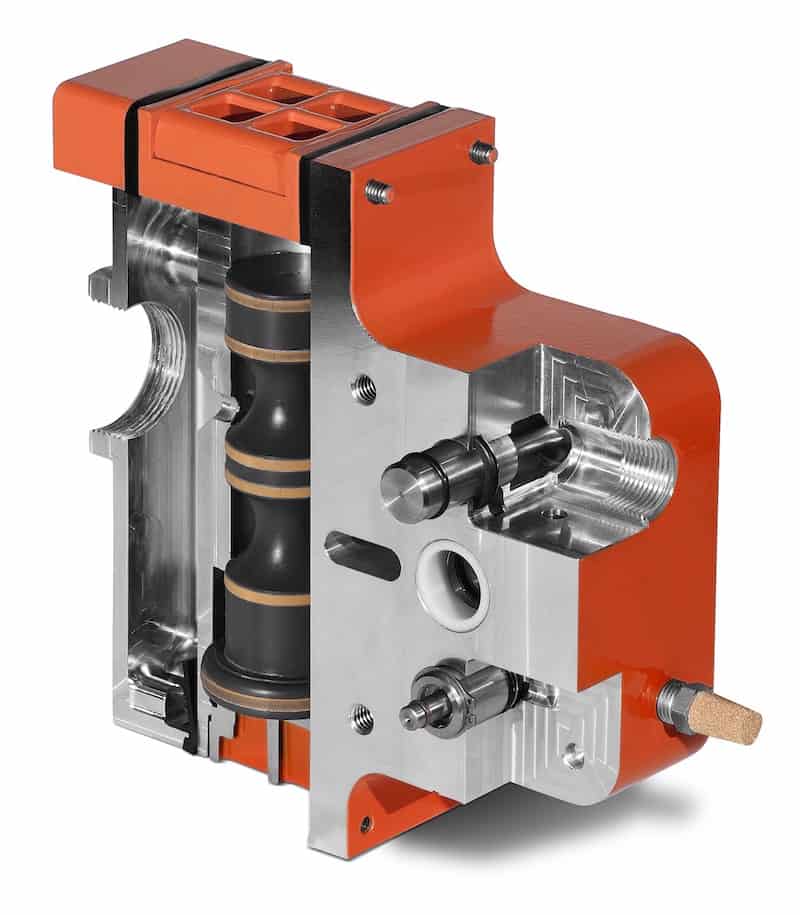

Evaluation revealed that air consumption was significantly impacted by an increase in air pressure at the end of each diaphragm stroke.

Specifically, when the shaft came to a full stop at the end of each stroke a shift signal would indicate that the flow of air should cease. However, there was a small time lag between the stopping the shaft and the sending of the signal, meaning that the full force of the compressor continued to push compressed air into the air chamber and was lost to the atmosphere upon exhaust.

Operating an air control spool reduces the amount of air that is allowed into the pump at the end of the stroke. This drastically reduces the amount of “wasted” energy that had traditionally been “force fed” into the pump.

This allows the AODD pump to experience up to 60% savings in air consumption, while delivering more yield per standard cubic feet per minute (scfm) than AODD pump models that feature legacy ADSs.

Through Thick and Thin – Air-operated Double Diaphragm Pumps In Chemical Processes

The reputation of AODD pumps is built on the technology’s ability to handle a wide range of liquids with varying characteristics. One of the most important is viscosity of the liquid, because the pump’s true best operational efficiency is only achieved if the lowest possible amount of scfm of air is consumed while delivering the highest possible flow rate, regardless of viscosity.

Specifically, slip is almost eliminated as it is controlled by the AODD’s ball check valves. Other technologies such as gear, screw and lobe pumps have fixed tolerances to control slip, which makes them unable to adequately adjust to viscosity changes.

The real benefit of the AODD pump is its ability to handle multiple or different viscosities without regard for equipment setup. For example, gear pumps may be a good choice for very thick oil or viscous liquids, but they are poor choices for thinner liquids like ethanol or water.

With the AODD pump it doesn’t matter if the fluid is thick, thin, particulate-free or laden with particulates; its design allows it to pull in the liquid, no matter its composition, and drive it downstream.

AODD pump manufacturers do publish viscosity correction tables, but these only help in predicting pump performance. In reality, the AODD pump does not need to change for liquids that have highly viscous or very thin consistencies’

Steps to improve the pump’s flow path will make it even easier to efficiently transfer highly viscous or particulate-laden liquids. In fact, some newer AODD pump models with redesigned and optimised wetted paths deliver flow rates up to 50% higher than legacy models.

This enhanced flow capability may also allow the operator to use, for example, a 2-inch pump where a 3-inch model may have been the choice in the past, with attendant initial cost of ownership and maintenance cost reductions – smaller pumps, smaller price.

It should be noted that the AODD pump does have a few performance limitations, most commonly on the suction side of the pump, since the only pressure that is available to bring the liquid to the pump is atmospheric.

In cases of extreme suction conditions, it is crucial that the pump should be located close to the source of the fluid. This will reduce the line friction leading to the pump. Whenever possible, the pump should be positioned below the supply tank, enabling gravity to assist the “feeding” of the pump.

Also, eliminating fittings and elbows on the suction side of the pump will help performance. Operators and system designers may additionally consider over-sizing the plumbing leading to the pump so as to reduce friction on the suction side.

Discussing Diaphragms

There’s no question that the improvements in overall AODD pump operation and ADS capabilities have been significant over the years, and the same can be said for diaphragm materials and design. As AODD pumps have begun to be used in more process-type applications the advances in diaphragm performance have kept pace.

Correct diaphragm material selection is critical to ensure safe AODD pump operation, with six primary factors to consider when choosing a diaphragm: chemical compatibility, temperature range, abrasion resistance, flex life, performance and cost.

To help meet these diverse operational criteria, the number of effective diaphragm materials has also grown and now consists of three basic subsets: Synthetic rubber (Neoprene, Buna-N, EPDM and Viton®), thermoplastic elastomers (TPE) (polyurethane, Santoprene® , Hytrel® and Geolast®) and Polytetrafluoroethylene (PTFE or Teflon®). Manufacturers have experts on hand to help pump users select the best diaphragm material and design for their applications.

Advances have also been made in diaphragm design that help make the AODD pump more hygienic in its operation, which allows its use in contamination-sensitive manufacturing applications like food and beverage, pharmaceutical and personal care.

Integral piston diaphragm designs place the shaft connecting plates within the diaphragm itself, which means that all product-entrapment areas and leak points between the piston and diaphragm have been eliminated, resulting in a reduction in the chance that product contamination or leaks can occur.

Integral piston diaphragms are easily cleaned and there is no interaction between the diaphragm and the outer piston plate that can lead to abrasive diaphragm failure.

For the chemical facility operator, downtime and pump maintenance are typically more expensive than the spare parts. This allows the pump to run twice as long before requiring maintenance and will translate directly to a healthier bottom line.

Chemically Speaking

So, what does all this mean for the chemical-processing industry? The complexity of chemical manufacture is highlighted by the number of so-called “unit operations” that must be completed during the overall manufacturing process.

One of the most critical unit operations is transferring liquids along the production chain. Because of the importance of the myriad transferring operations within the entire chemical manufacturing process – raw materials to storage tanks, raw materials to blending tanks, finished products into fixed-weight containers, etc. – facility operators need to identify the best pumping technology for the job, one that possesses the versatility to perform reliably and efficiently at any number of points in the production hierarchy.

Historically chemical manufacturers have considered that centrifugal pumps were the best technology for transfer operations within the chemical plant, for several reasons:

- Centrifugal pumps work best with thin, water-like fluids.

- A kind of “if it ain’t broke don’t fix it” attitude has made the centrifugal pump an easy fallback option.

- Centrifugal pumps are perceived to have a lower operating cost when compared to the operations of an AODD pump.

A closer look, through, shows that the centrifugal pump doesn’t appear to be the all-conquering technology that is required for efficient and optimised chemical-processing applications.

When a centrifugal pump works to the right of BEP other problems can be created. Specifically, the level of net positive suction head (NPSH) required increases, which may cause cavitation to occur.

Since the liquid-transfer process in the chemical industry is often managed in batches, insufficient NPSH may be harder to detect, but it will deteriorate the pump’s operational capabilities continuously, meaning that the pump’s ability to handle any cavitation that occurs will be compromised.

By comparison, the fluid-delivery curve for an AODD pump is very similar to that of the centrifugal unit, without the negative behaviour that occurs when running off the BEP.

The performance of AODD pumps is based on the inlet air pressure supplied and the system pressure it encounters. If adequate suction pressure is available, fluid will flow into the pump and be discharged based on the relationship between the air pressure operating the pump and the system pressure.

The larger the pressure differential the faster the pump will operate, and when the differential is reduced, the pump’s operation will slow. This is referred to as “infinitely variable speed operation.”

If the system pressure increases unexpectedly, the pump will operate until the inlet air and system pressure are equal and the AODD pump will stop – in what is termed a “deadhead” condition – with no equipment damage.

The system remains pressurised, but no differential pressure exists to continue driving fluid. The pump will restart when the system pressure falls below the operating air pressure, which is particularly important in batch processes.

It is widely recognised that a closed valve can wreak havoc on a centrifugal pump as it can with different positive displacement pump technologies operating against a closed valve.

This can very quickly cause damage or destroy a system by reaching the burst pressure of the plumbing. If a valve is restricted on the inlet side of a centrifugal pump, the pump can cavitate, leading to impeller and volute damage.

If the inlet were closed completely, the operator should expect bearing and wear-ring failure due to heat build-up. This not so with when operating an AODD pump as the pump will slow and if the inlet were closed completely, the pump would stop, waiting for the inlet line to be open once more, when it would resume its pumping operations.

Summing up, AODD pumps can match the supposed advantages of centrifugal pumps while also shining an even brighter spotlight on the centrifugal pumps operational disadvantages.

Conclusion

Operators of industrial pumps have always demanded that pumps perform their duties reliably and with a limited amount of downtime, wear and replacement costs.

The AODD pump has been able to consistently meet those demands and has become a go-to pumping technology where basic liquid-transfer capabilities are required.

Today it is not only enough to perform the required task; the pump must do so in the most cost effective and environmentally friendly way possible, with the lowest affect on the bottom line and carbon footprint.

That creates a quandary for the chemical manufacturer who must perform that cost and environmentally sensitive juggling act while still creating intricate and complex products.

Many have found that relying on previously tried-and-tested pumping technologies may not be enough anymore and have begun to look for alternatives.

AODD pumps, which possess many enviable operational characteristics, can make them the ideal choice for chemical manufacturers who are searching for a pump technology that meshes cost-conscious energy consumption with streamlined flow rates.

Note: Viton®, Teflon® and Hytrel® are registered trademarks of DuPont ™ Company, and Santoprene® and Geolast® are registered trademarks of ExxonMobil.