TL;DR: Radar Measurement in Water & Wastewater

Radar technology offers a highly accurate, contactless method for measuring both water level and flow in open and partially filled channels. Unlike submersed sensors, radar functions reliably even in chemically contaminated or sediment-heavy environments. Its key advantages include minimal maintenance, fast installation and independence from medium properties.

While installation height and environmental conditions must be considered, radar is ideal for use in wastewater treatment plants, rivers and stormwater systems. With both wired and energy self-sufficient models available, radar solutions from NIVUS provide flexibility and precision across a wide range of industrial water management applications.

Water management is becoming increasingly important as water use increases globally, regulations become stricter, and the climate crisis prevails. Responsible management is necessary because of the critical role water plays for human survival and stability of the planet.

Mismanagement of the resource can result in serious consequences, including drought, flooding or degradation of water quality. Proper management can also help optimise processes to save resources.

Effective water management requires accurate information as a basis for decision-making. There are several aspects of water that can be managed, two main aspects that will be discussed within this article are the fill level (height) in channels or collection basins and the volumetric flow in channels. One highly accurate, simple, and cost-effective method of performing these two measurements is with the use of radar technology.

Radar measurement instruments are available for measuring both water level (height) and velocity, which can be combined to calculate the total flow rate. The distinction between these two applications, prerequisites for their application and further benefits of each technology will be detailed in the two upcoming main subsections.

Know How

Radar technology is a contactless method for measurement in open and partially filled channels, particularly useful in water and wastewater management, but also applicable for measurements of different liquids or even solid materials.

The radar sensor sends out electromagnetic signals with a certain frequency, at a constant or modular value. This signal is reflected as it contacts the water (or other) surface, providing information related to the fill level or flow velocity, depending on the device used.

Because of its contactless nature, this measurement principle can be used in applications where other technologies requiring submersion in the medium could not be used, or would at least be much more difficult and costly. NIVUS GmbH offers a range of radar measurement products both for fill level and velocity, focused for water and wastewater applications, but also applicable for other applications.

Benefits & Limitations of Radar Technology

Radar measurement systems provide many benefits over other level and velocity measurement technologies. Contactless solutions make the installation and maintenance much quicker in comparison to submersed sensors and do not interrupt any processes or require divergence of flow.

Relative to other contactless measurement methods such as ultrasonic, radar functions largely independent from the properties of the measurement medium (e.g. conductivity, density, temperature, and viscosity).

“Unlike submersed sensors, radar functions independently of medium properties like conductivity, density, and viscosity, making it highly versatile.”

For flow measurement, the contactless feature is extra beneficial in channels with high levels of sediment or where wastewater is chemically contaminated from industrial processes. Submersed sensors in these situations could provide less reliable measurements or become easily damaged, both leading to extra expenses.

Along with all these benefits come a few limitations of radar measurement. One main limitation is that these devices do not work if they become flooded under high-level conditions, or if they are mounted too high above the surface. The installation height and sensor-specific measuring range must therefore be chosen wisely in advance.

The width of the channel also plays a role in the mounting height because each device sends out its signal in a different shaped/sized beam angle. Therefore, it is important to make sure the edges of the channel, pipe, or container, and any other objects such as the climbing irons in a manhole are not within the view of the sensor, or are otherwise accounted for in the parametrisation of the device which is possible with the NIVUS devices.

Technical Properties of Radar Technology

The various models of radar-based level sensors cover very different measuring ranges from a few centimetres up to several tens of metres. The chosen sensor must suit the application.

Furthermore, many different operating frequencies are available on the market. This sensor characteristic can play an important role in applications in an industrial environment, as there may be strict regulations on the frequencies used.

In addition, there are of course other technical features whereby the models used in the sensors or measurement transmitters can differ.

“Radar flow measurement excels in high-sediment or chemically contaminated water, where submersed sensors may be unreliable or easily damaged.”

Water Level Measurement

Knowing the accurate fill level of a water channel, basin, or other industrial container is essential for proper management of the medium. Overfilling or floods can then be avoided, or at least the damages from such events can be minimised with early knowledge of the increasing levels. The following section presents level measurement using radar technology.

It discusses the contactless measurement concept and the necessary prerequisites for measurement, which result from the mode of operation. With this knowledge, various designs and specific solution modules are presented, followed by practical applications.

Level Measurement Principle

Radar level sensors use the speed of the transmitted electromagnetic waves, the signal travel time, and the vertical mounting position of the device to calculate the fill level. The sensor emits its waves in the direction of the water surface.

These waves are reflected by the liquid and partially sent back to the sensor. The time between the emission of the electromagnetic waves and the detection of the reflection provides information about the distance between the sensor and the water surface. For a given mounting height of the sensor, the actual level can be determined using the following formula:

Prerequisites

To ensure proper and accurate operation, this measurement principle, like any technology, depends on the fulfillment of specific prerequisites. The sensor has to be installed parallel to the water surface. Furthermore, the path between sensor and water surface must remain clear. There should not be any obstacles, for example stones, weed flags, climbing irons, rods, sole jumps or thresholds in the sensor’s field of vision.

In contrast to velocity radar systems, radar-based level measurement is relatively insensitive to hydraulic disturbances. As long as the disturbances don’t lead to implausible level measurements, only few conditions need to be observed.

Types of Devices

In practice, radar-level sensors can be cable-connected to a measurement transducer providing power supply and storage, processing, and transmitting of the measurement data. These sensors can be integrated into any system.

Furthermore, there are energy-self-sufficient solutions that consist of the actual radar level sensor, data transmission unit and batteries in a single housing. These compact solutions provide a very simple, intuitive and robust level measurement. NIVUS offers three different versions of radar sensors to fit all applications.

Application Examples

Many typical applications of radar level measurements can be found in the fields of water and wastewater management. Monitoring of sewer channel networks, water treatment plants, rivers, and storage basins is crucial for functioning water management. These types of channels and basins can contain water from and for a variety of applications such as drinking water or hydro-power. In addition to these applications, radar-based level sensors can also be used to fulfil tasks in the process industry.

Flow Rate Determination

The determination of flow rates is indispensable for many processes when it comes to monitoring water or wastewater volumes. In order to ensure continuous flow rate determination, a measurement system must be capable of providing optimum velocity detection, as well as accurate water level detection. The radar measurement method allows contactless flow velocity metering, which is a value used to calculate the volumetric flow.

Flow Measurement Principle

Velocity radar measurement uses the doppler principle to measure velocity of the waves on the surface. The velocity sensor is typically mounted at a 45° angle to the water surface, forcing a significant portion of the reflected signal to be sent back to the sensor by the surface waves.

The waves sent from the sensor become compressed when they contact waves on the water surface, creating a frequency shift between the sent and reflected signals. This frequency shift is evaluated by the doppler principle and produces the surface velocity.

In order to obtain a value for total flow in a channel, the wetted cross-sectional area at the measurement point must also be known. This is computed from the geometry of the channel and the level of the water, which can easily be measured using various types of water level sensors.

Figure 6: Schematic drawing of radar flow measurement principle

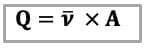

With the water level, channel geometry, and possibly other details about the channel such as bed material or sediment load, the measured surface velocity can be input into hydraulic models that calculate the average flow velocity of the channel, based on these attributes. The accuracy of this velocity and the final flow deducted from this velocity depend on the quality of the embedded hydraulic flow models. The volumetric flow is then computed as follows:

Q = Flow rate

¯v = Average velocity

A = Wetted cross-sectional area

Formula 2: General flow rate calculation

Prerequisites

As with any technology, there are certain prerequisites that need to be fulfilled for this measurement principle to properly and accurately function. These have to do with the physical installation of the sensor, properties of the measurement site, and possible changes to these properties in open settings, including variability in weather conditions.

The sensor should be mounted in the middle of the channel, when possible, because of the heterogeneous nature of flow profiles. The central mounting ensures the measurement window that is projected onto the surface is properly covering the surface as per the technical requirements of the specific device.

As described, the signal reflects off the surface waves, so without waves this technology cannot function. Waves need not be large, typically just large enough that the human eye can observe them is sufficient for successful measurements. These waves should be consistent with the true flow of the water. This means that nothing should be blocking the flow downstream close by causing surcharge or backwater, no extra inflows or curves should be close by, and effects from weather such as wind and rain should be avoided or minimised by mounting sensors under bridges or other protected areas.

Further Benefits

“With options from wired sensors to energy self-sufficient compact solutions, radar technology offers precise solutions for diverse water management needs.”

The actual measurement method itself provides benefits, allowing it to be used when other techniques may not be an option because of physical device size or hardware limitations. Radar can accommodate a high-velocity measurement range, up to 15m/s with some devices. Furthermore, these high velocities can be measured even at extremely low water levels, making it a very versatile and flexible measurement solution.

Application Examples

Radar flow measurement is, as stated, used for open and partially filled channels, where other flow measurement technologies may not be suitable or practical to install. Applications include inlets and outlets at wastewater treatment plants or in manholes for storm/wastewater with a high sediment load, which could damage or affect the measurement results of submersed [LW1] sensors. Another common application is rivers, from narrow with low flow to very wide, high-flow rivers, in which case multiple sensors could be mounted for increased accuracy.

Summary

Measuring level and volumetric flow using radar technology is becoming increasingly popular because of its contactless nature and accurate results. Radar stands out for its wide range of uses in many partially filled and open channel applications, as well as in collection basins and other industrial tanks requiring level measurement.

Contactless measurement makes these systems highly robust, and with the additional ease of maintenance, radar metering is particularly suitable for applications featuring high sediment loads or in cases with chemical contaminants, when it is not possible to install sensors within the medium.

Radar level and flow measurement is therefore a very useful system for many applications in the wastewater and other industrial fields. Due to the large range of available products and their technical differences, there is no one-size-fits-all solution, but instead precise solutions available for each application.

There are various solution modules in both radar level and flow measurement technology, ranging from simple, wired sensors to complete, energy self-sufficient compact solutions including data transmission. As devices and sensors become increasingly networked, radar-based level measurements with data transmission – whether by means of a connected measurement transducer or via the integrated data transmission unit in a compact solution – open up many new possibilities!

About the authors:

Leonhard Werthebach

Leonhard Werthebach was born in 1994 in Leverkusen, Germany. After completing his M.Sc. in Industrial Engineering in 2021 at the Karlsruhe Institute of Technology (KIT), he started working for NIVUS GmbH where he has been working as a Product Manager ever since.

[LW1]Oben heißt es „submersed“, hier „submerged“ – geht beides?

FAQs: Radar Technology for Level & Flow Measurement

What makes radar suitable for water and wastewater applications?

Radar sensors are contactless accurate and unaffected by medium properties like density or temperature making them ideal for harsh environments

How does radar measure water level?

By emitting electromagnetic waves and measuring the time it takes for them to reflect off the water surface the sensor calculates the fill level

How does radar determine flow rate?

Radar uses the Doppler effect to measure surface velocity which when combined with level data and channel geometry provides total flow rate

What are the benefits of radar over submersed sensors?

Radar offers quicker installation less maintenance and better performance in sediment-heavy or chemically aggressive environments

Are there limitations to radar measurement?

Yes radar does not work when submerged or when mounted too high and needs a clear view of the water surface to function correctly

What types of radar devices are available?

Both wired systems and energy self-sufficient compact units with integrated data transmission are available for diverse site needs

Where is radar flow measurement commonly used?

It is used in wastewater plant inlets stormwater manholes and rivers where submersed sensors may be damaged or inaccurate

How does radar help optimise water management?

It provides real-time reliable data for decision-making helping prevent floods reduce downtime and ensure regulatory compliance